Group Members

Postdoctoral Researchers

Tawqeer Nasir Tak

Ph.D.: IIT Bombay, India

Aalok Jha

Ph.D.: IIT Kanpur, India

Yangyuanchen Liu

Ph.D.: Duke University

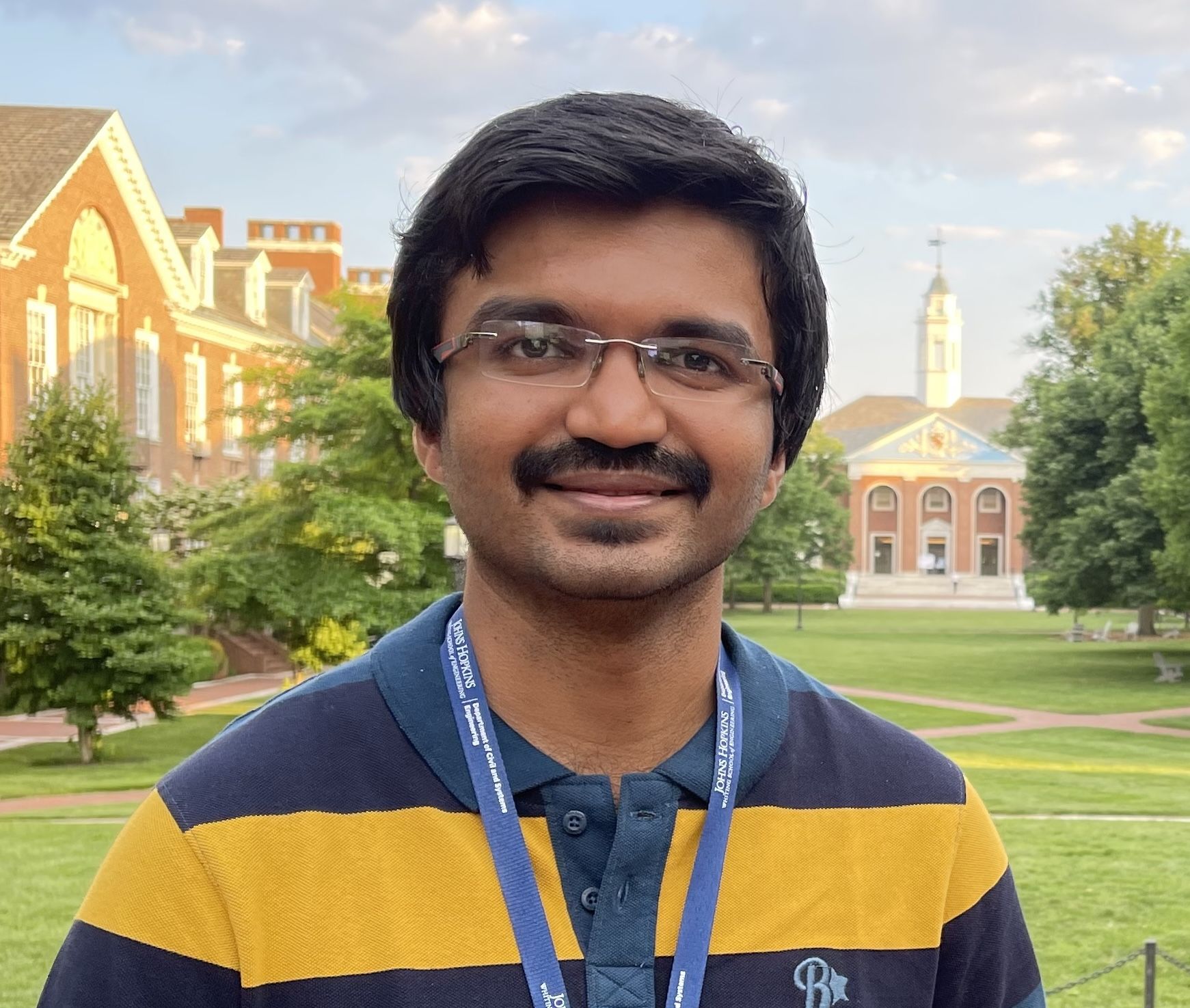

Prajwal Kammardi Arunachala

Ph.D.: Stanford University (Sept ’24)

M.S.: Stanford University (Apr ’19)

B.Tech.: Indian Institute of Technology Bombay (May ’17)

Improving existing phase field fracture models for Ti-alloys, extending them to account for fatigue loading, and ensuring effective parametric upscaling for large-scale industrial applications.

Sponsored by Office of Naval Research

Current Ph.D. Students

S.K. Gargeya

Kishore Nair

Joshua Stickel

Lucas Ferreira

Nolan Strauss

Isabella Snyder

Gino Varkey